Automotive for aligning perfection

Aerospace For The Finished Surfaces

Medical For Smooth Finishes

General Engineering For Precision Edges

Jewellery for Added Glitter

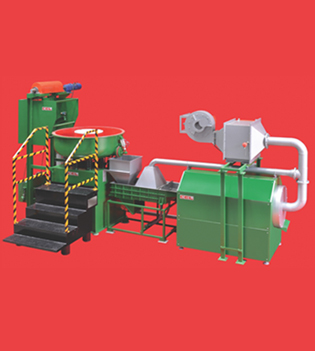

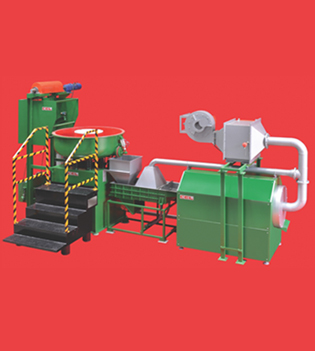

Ceramed Product Range

CN Series

Vibratory Systems

Rotary Dryer

Drying Systems

Vibratory Dryer

Drying Systems

CM Series

Vibratory Systems

CN Spiral Series

Vibratory Systems

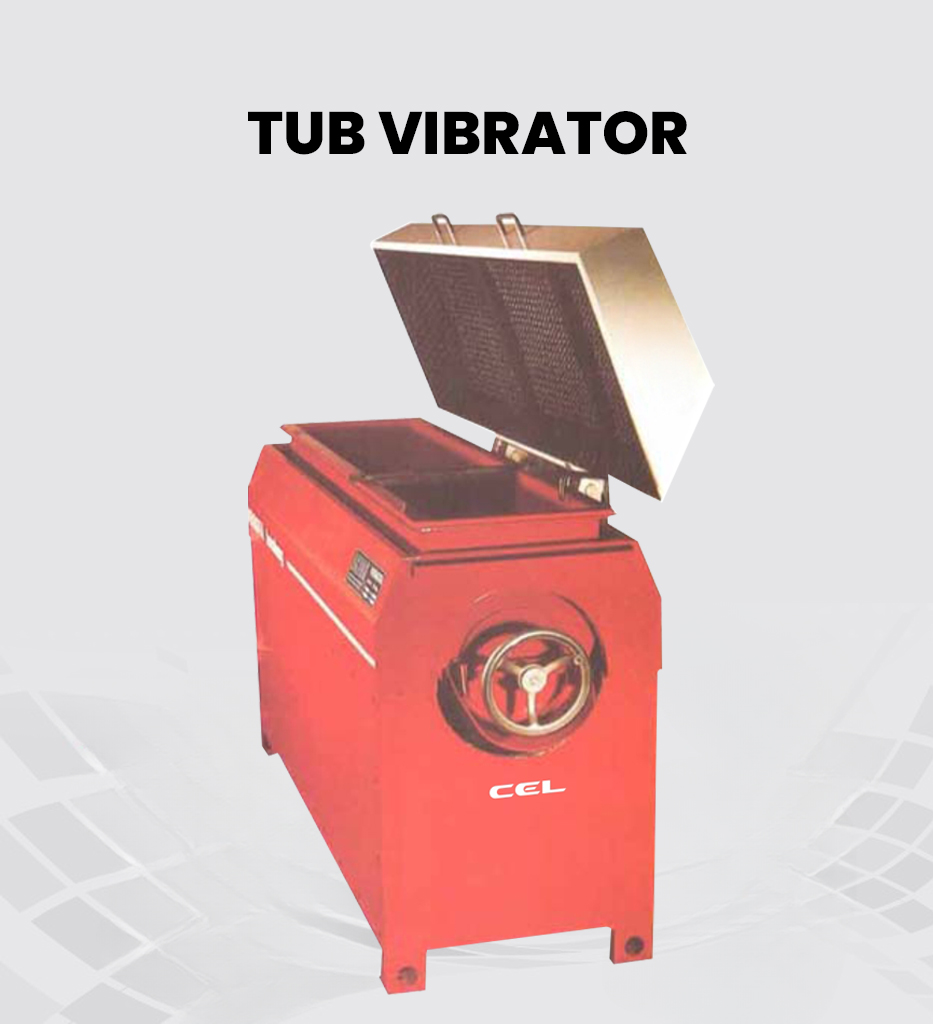

Tub Vibrator

Vibratory Systems

Ceramed Engineers Limited.

Ceramed offers the widest range of Quality Metal Surface Finishing machines that are suited for operations like, deburring, descaling, derusting, polishing and super polishing. These surface finishing machines find their application in a wide range of industry verticals. Besides, Ceramed also manufactures industrial dryers, including rotary dryers and vibratory dryers.

20+

Finishing Machines

35+

Years Experience Our Company

Your Ultimate Destination for Surface Finishing Excellence

At Ceramed Engineers, we don’t just sell machines; we deliver solutions that transform the way you approach surface finishing. With years of expertise and a passion for innovation, we’ve become a trusted name in the industry, providing state-of-the-art surface finishing machines that cater to a wide range of industrial applications. Whether you’re looking for vibratory finishing machines, centrifugal finishing machines, or customized solutions, we’ve got you covered.

400+

Completed Events in India

What We Offer

Vibratory Finishing Machines:

- Perfect for deburring, polishing, and surface smoothing.

- Ideal for industries like automotive, aerospace, and jewelry.

- Designed to handle small to large batches with consistent results.

Centrifugal Finishing Machines:

- High-speed finishing for precision parts.

- Reduces processing time while delivering unmatched quality.

- Perfect for delicate components that require a gentle yet effective finish.

Customized Surface Finishing Solutions:

- Tailored to meet your unique requirements.

- Compatible with a variety of media and compounds.

- Suitable for industries like medical devices, electronics, and more.

Industries We Serve

Our surface finishing machines are trusted by a wide range of industries, including:

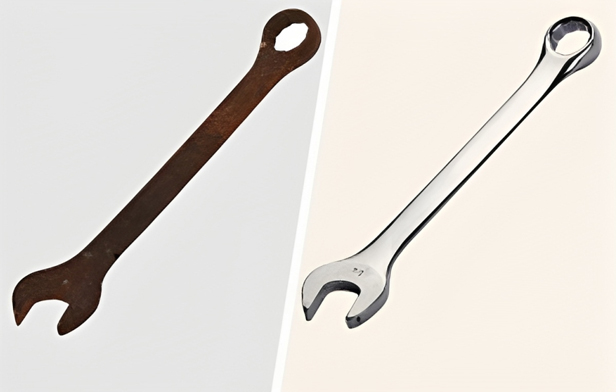

Automotive

For polishing engine components, gears, and transmission parts.

Aerospace

For finishing turbine blades, landing gear, and other critical components.

Medical

For polishing surgical instruments and implants to meet stringent hygiene standards.

Electronics

For deburring and smoothing connectors, casings, and other precision parts.

Quality is at the heart of everything we do. From the materials we use to the technology we employ, every aspect of our surface finishing machines is designed to deliver unmatched performance. We rigorously test our machines to ensure they meet the highest industry standards, so you can trust them to perform day in and day out.

We believe in responsible manufacturing. Our machines are designed to minimize waste, reduce energy consumption, and optimize resource usage. By choosing Ceramed Engineers, you’re not just investing in superior surface finishing – you’re contributing to a greener, more sustainable future.

At Ceramed Engineers, we’re more than just a supplier – we’re your partner in success. We take the time to understand your needs, challenges, and goals, and we work closely with you to deliver solutions that make a real difference.

Whether you’re looking for vibratory finishing machines, centrifugal finishing machines, or a completely customized solution, we’re here to help. Let’s work together to achieve the perfect finish for your products.

Contact Us Today

Ready to take your surface finishing to the next level? Reach out to Ceramed Engineers today. Our team of experts is ready to answer your questions, provide recommendations, and help you find the perfect solution for your needs.

Who We Are

At CERAMED Engineers, we’re passionate about helping businesses achieve perfection in metal surface finishing and super finishing. We’re not just a manufacturer – we’re your partner, working closely with you to deliver tailored solutions that meet your unique needs. Whether it’s descaling, deburring, polishing, or super polishing, we’ve got the expertise and technology to transform surfaces of any size or specification.

With years of experience under our belt, we’ve built a reputation for creativity, integrity, and reliability. From the medical equipment industry to aerospace, we’ve helped countless businesses achieve flawless finishes, improve productivity, and reduce costs.

What drives us? A commitment to quality and a focus on innovation. We’re constantly researching and improving our techniques to bring you cutting-edge solutions that set you apart from the competition. When you work with CERAMED, you’re not just getting a machine – you’re gaining a partner who’s invested in your success.

CERAMED Engineers – Precision, Trust, and Excellence in Every Finish.

Why Choose Our Surface Finishing Machines?

Our finishing machines are designed for exceptional performance, offering:

- Superior Surface Finishing: Achieve flawless finishes on metals, plastics, ceramics, and more. Our machines ensure consistent burr removal, descaling, and polishing.

- Cost-Effective Operations: Save time and resources with efficient processing. Our machines reduce operational costs while maximizing output.

- Customizable Solutions: Tailor our machines to meet your industry’s specific requirements and applications.

Applications of Vibro Finishing Machines

Our machines serve various industries, including:

- Aerospace and Automotive: Ideal for deburring, polishing, and descaling components.

- Jewelry Industry: Precision polishing for intricate designs.

- Manufacturing and Engineering: Enhance the durability and aesthetic appeal of industrial parts.

Explore Our Advanced Surface Finishing Machines

We offer a diverse range of surface finishing machines designed for various applications across industries. Whether you need deburring, polishing, or smoothing, our machines guarantee a flawless finish every time.

Key Features:

- Multi-stage processing options

- Durable construction for long-term use

- Energy-efficient technology for sustainability

Centrifugal Finishing Machines: A High-Performance Alternative

For high-speed and precision finishing, our centrifugal finishing machines are ideal. They operate at high centrifugal forces for rapid and uniform finishing of smaller components.

Advantages of Centrifugal Finishing Machines:

- Compact and efficient designs

- Ideal for delicate and intricate parts

- Faster processing times compared to conventional methods

Unique Offerings from Ceramed Engineers

We go beyond selling machines. We are committed to:

- Expert Consultation: Our specialists work closely with you to understand your needs and recommend the best solutions.

- Comprehensive After-Sales Support: From installation to maintenance, we ensure your machines run smoothly with minimal downtime.

- Eco-Friendly Practices: We prioritize sustainability by designing machines that minimize waste and energy consumption.

Partner with Ceramed Engineers Today

At Ceramed Engineers, we deliver exceptional surface finishing solutions. With a legacy of trust and innovation, we empower businesses to achieve unparalleled product quality.

Contact us today to learn more about our vibro finishing machines, surface finishing machines, and centrifugal finishing machines. Let us help you elevate your manufacturing processes to new heights!

Ceramed Engineers - Solutions

Across industries, varied types of products have specific surface finish requirements. Ceramed has over the last decade catered to this needs with innovative, quality and economical solutions.

From bringing shine to jewelry to finishing precision equipments and components, Ceramed has customized solutions for each need. Effectively handling the growing service and production volumes, we have kept pace with both technology and quality to always deliver solutions on time to our clients.

Application Strength

Our consistent quality and on time deliveries have built strong customer trust over the years. Enhancing our processes and techniques with the latest technology interventions has helped us offer our customers a variety of options and improved quality everytime.

Virtual Shop

The Descaling, Deburring, Polishing and Super polishing solutions offered by Ceramed involves the introduction of the object into the CM and the CCF machines. Suitable ceramic media and compounds corresponding to specific solutions are also used during the process. The CM and CCF machines through the vibratory, centrifugal and rotary motions, deliver the desired finishing.

Customer Experiences

Minda auto components ltd.

L. G. Balakrishnan & bros ltd (Deputy Manager- PED Chains)Ceramed is committed to the work and has been providing us timely service as well as good customer support

Jindal Stainless (Hisar) Limited

(Senior Manager –Materials)CEL - Most important supplier with consistent in quality and delivery

Trelleborg Industrial Products India Pvt Ltd

(Deputy Manager – Supply Chain)Equipments from M/s Ceramed Engineers are standard in quality with good performance

Usha International Ltd

(Senior General Manager – R&D)Satisfied with the products supplied by Ceramed

Mr. Santanu Basu

(Senior General Manager – R&D - Usha International Ltd)1. Ceramed always supplies the best quality & productivity equipment. 2. Continuous availability of machine parts and spare parts. 3. Good service back-up.

Mr. Navin Khatri

(Senior Manager –Materials - Jindal Stainless (Hisar) Limited)Equipments from M/s Ceramed Engineers are standard in quality with good performance

Mr. Dimpath Monnappa p

(Minda Auto Components LTD.)Ceramed is committed to the work and has been providing us timely service as well as good customer support

D. Jawahar

Deputy Manager- PED Chains - L. G. Balakrishnan & Bros LtdCEL - Most important supplier with consistent in quality and delivery

Mr. Praveen Rotti

Deputy Manager – Supply Chain - Trelleborg Industrial Products India Pvt LtdSatisfied with the products supplied by Ceramed

Mr. Dimpath Monnappa P

Minda Auto Components LTD.Ceramed is committed to the work and has been providing us timely service as well as good customer support

Product Enquiries

Looking for a fast and hassle-free way to reach us? Just complete our contact form, And We'll Get Back To You As Soon As Possible.

We welcome your input! Whether you have inquiries or wish to engage in a discussion, please don't hesitate to contact us. Connecting with us is easy – simply select your preferred method.

9164504222

sales@ceramedengineers.com

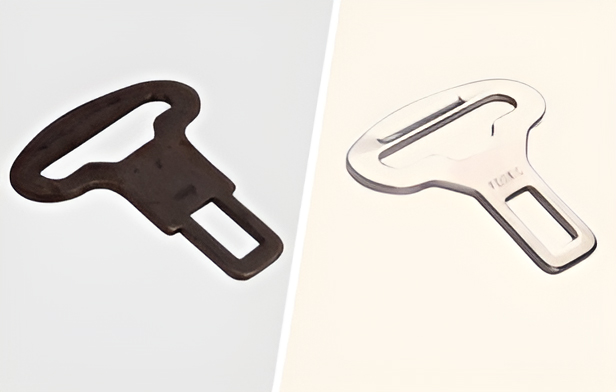

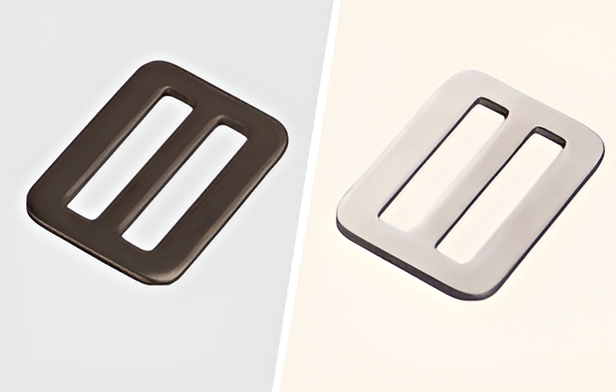

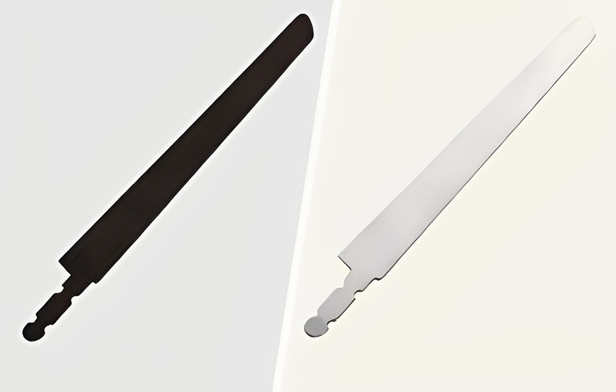

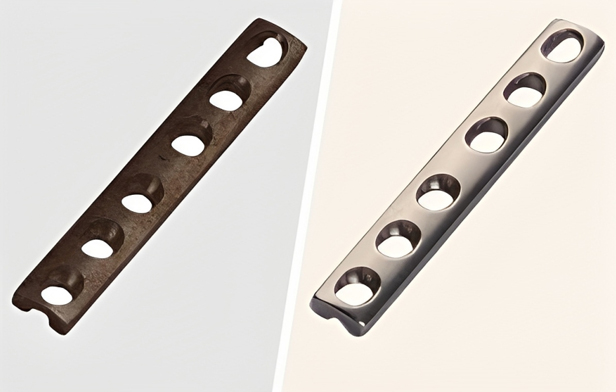

Before & After