- Home |

- Oxygen Probe

Oxygen Probe

Oxygen Probe

Description :

The O2 Probe, is a cost effective option, offering high reliability, compatibility and accuracy for the measurement of carbon potential (%C) and temperature (°C). It is based on the ZrO2 C-700 electrolyte. This probe measures the oxygen concentration inside the furnace. The Probe construction is robust to withstand harsh environments. Probes are virtually maintenance-free and provide highly accurate control of furnace atmospheres. It incorporates a long life steel sheath especially formulated for carburizing atmospheres.

Specification

| Voltage generated by the probe | 0-1200mV |

| Thermocouple | Type K or R |

| Length of probe | 600mm, 700mm, 750mm, 850mm, 1000mm |

| Service temperature | 700 – 1100°C |

| Air flow | 1 l/h (reference) 300 l/h (cleaning) |

| Diameter | 26mm |

| Sheath | Sandvik 253 MA |

Features

- The functional principle of an oxygen probe is based up the comparison of the two oxygen partial pressures in two separate gaseous mediums. The zirconia which represents the measuring element has faults in its crystal structure, i.e. some of the sites which is a typical feature of this ceramic material. Thus, the measuring element becomes conductive. The voltage generated represents a relation between the relative difference of the oxygen concentrations and the temperature of the heat treatment atmosphere.

- In order to compare the partial pressures, the oxygen probe must be supplied with a gas of a known content of oxygen (ambient air : % o2 = 20.9%) this is what we call reference air. Moreover, the oxygen probe is equipped with a thermocouple allowing measurement of the actual treatment temperature. Thus, the user who knows the CO content either by analysis or by theoretical calculation and who takes into account the values measured by the oxygen probe system is able to determine the carbon potential in the heat treatment atmosphere.

- The measuring element of an oxygen probe has a limited lifetime. Its surface layer changes depending on the impurities which are found in the heat treatment atmosphere. Therefore the user should replace the measuring element when its impedance exceeds the tolerances admitted.

Applications

There are two simple tests that can be performed regularly while the probe is in service. If the probe fails either of these two tests, it should be replaced.

Check Probe Impedance

The impedance of a probe will gradually increase as the probe is used. The impedance of the brand new probe should be measured at the normal operating temperature then at regular intervals, at the same temperature. If the impedance abruptly changes or increases to 10 times more than the initial value, there may be a problem with the probe.

Check Reference Air Response

While the probe is in use, quickly shut off the reference air supply. The probe output signal gradually fall by a few mV in one minute. If the change is more than 25 mV, the sensor has probably cracked and will give inaccurate readings.

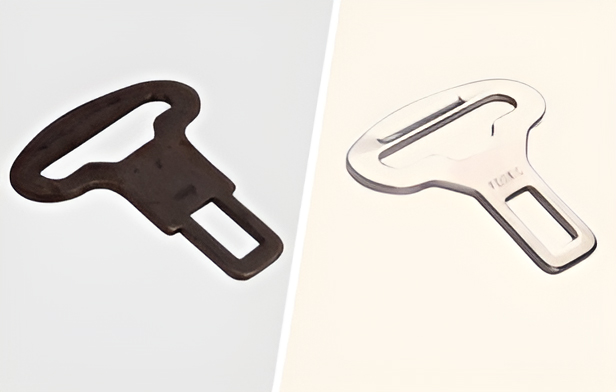

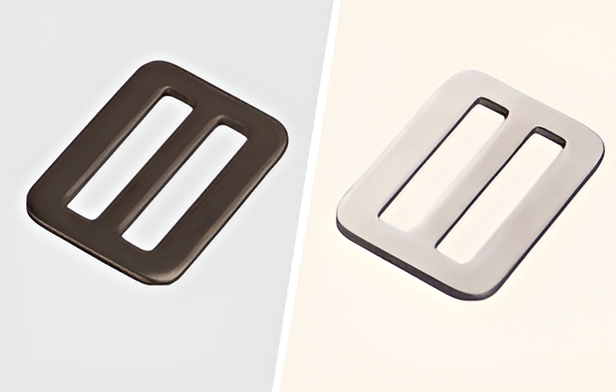

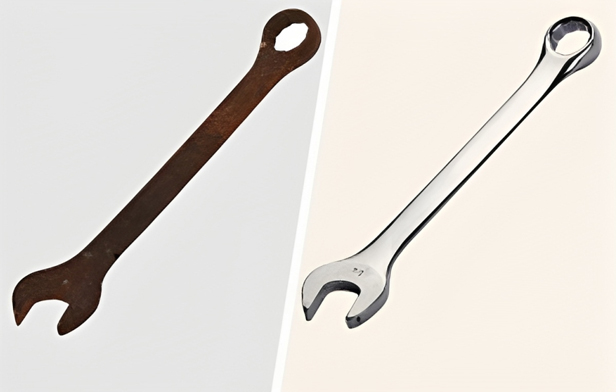

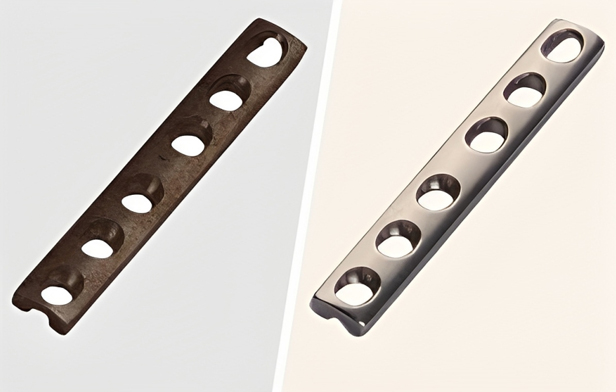

Before & After

Customer Experiences

Minda auto components ltd.

L. G. Balakrishnan & bros ltd (Deputy Manager- PED Chains)Ceramed is committed to the work and has been providing us timely service as well as good customer support

Jindal Stainless (Hisar) Limited

(Senior Manager –Materials)CEL - Most important supplier with consistent in quality and delivery

Trelleborg Industrial Products India Pvt Ltd

(Deputy Manager – Supply Chain)Equipments from M/s Ceramed Engineers are standard in quality with good performance

Usha International Ltd

(Senior General Manager – R&D)Satisfied with the products supplied by Ceramed

Mr. Santanu Basu

(Senior General Manager – R&D - Usha International Ltd)1. Ceramed always supplies the best quality & productivity equipment. 2. Continuous availability of machine parts and spare parts. 3. Good service back-up.

Mr. Navin Khatri

(Senior Manager –Materials - Jindal Stainless (Hisar) Limited)Equipments from M/s Ceramed Engineers are standard in quality with good performance

Mr. Dimpath Monnappa p

(Minda Auto Components LTD.)Ceramed is committed to the work and has been providing us timely service as well as good customer support

D. Jawahar

Deputy Manager- PED Chains - L. G. Balakrishnan & Bros LtdCEL - Most important supplier with consistent in quality and delivery

Mr. Praveen Rotti

Deputy Manager – Supply Chain - Trelleborg Industrial Products India Pvt LtdSatisfied with the products supplied by Ceramed

Mr. Dimpath Monnappa P

Minda Auto Components LTD.Ceramed is committed to the work and has been providing us timely service as well as good customer support