- Home |

- CM Series

CM Series

Vibratory finishing machines use the principle of centrifugal force to cause vibrations to the work bowl thereby processing the components to the desired finish. The equipment comprises of a work bowl mounted on a rigid base frame.

Ceramed’s Vibro finishing machine uses a powerful imported vibratory motor, made of special grade casting, and heavy duty spherical roller bearings. Springs are provided between the work bowl and base frame.

During operation, a mass of components along with a suitable ceramic media and chemical compound is introduced into the work bowl, the whole mixture rotates inside the bowl in a spiral and rotary motion causing the ceramic media to rub against the components continuously thus imparting the desired finish to the components.

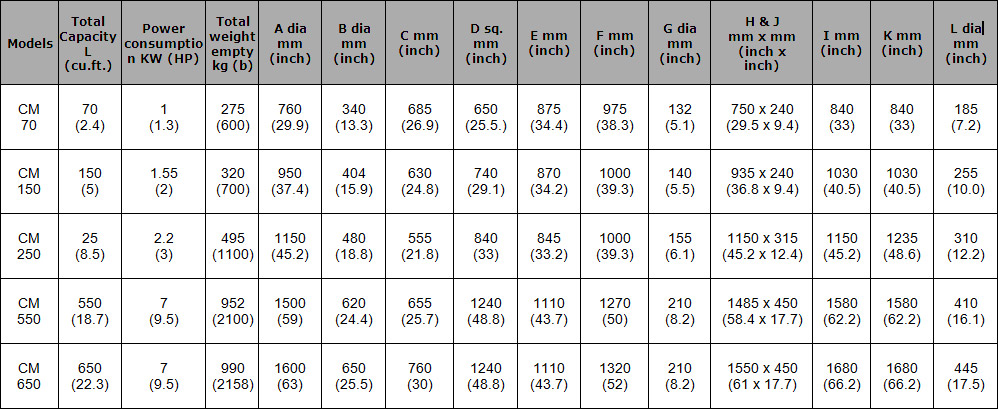

Specification

Features

- Heavy duty flange type vibratory motor with adjustable amplitude for fast & effective process.

- Hot poured polyurethane lining with 12-16mm average thickness and the hardness approximately 75-80 shore A for long life.

- Raw materials and components used and quality standards employed for manufacture, ensure trouble free performance.

- The springs are specially designed to withstand heavy load and in the manner that they deliver spiral and rotary motion of the components and media in the bowl.

- Standard electrical switch gear items with safety features are provided along with the supply.

- The machine is mounted on anti-vibration pads.

- Only High tensile SS bolts are used.

Applications

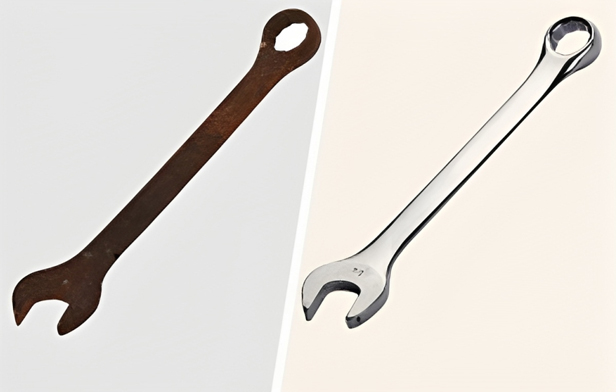

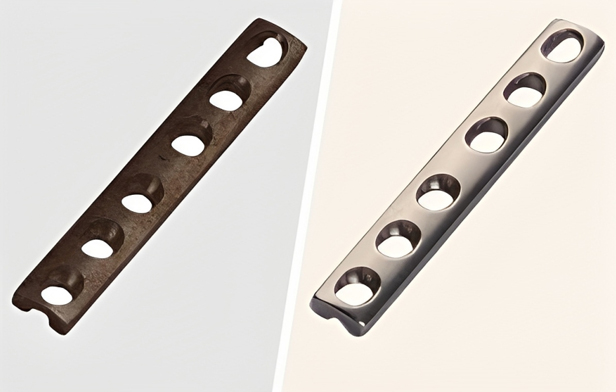

- Deburring

- Polishing

- Descaling

- Super finishing

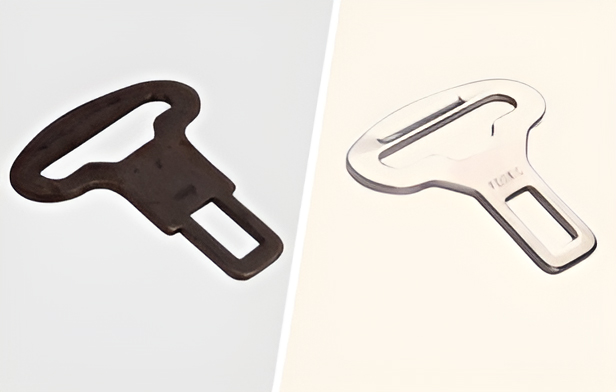

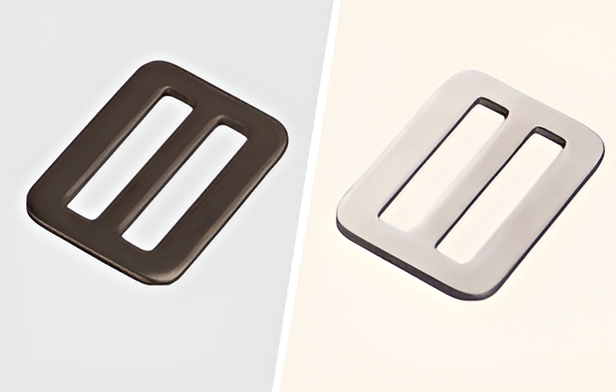

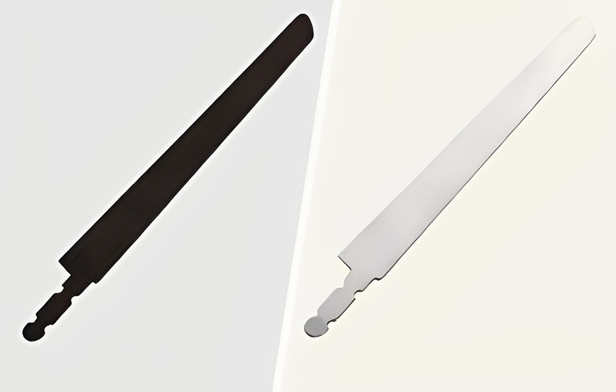

Before & After

Customer Experiences

Minda auto components ltd.

L. G. Balakrishnan & bros ltd (Deputy Manager- PED Chains)Ceramed is committed to the work and has been providing us timely service as well as good customer support

Jindal Stainless (Hisar) Limited

(Senior Manager –Materials)CEL - Most important supplier with consistent in quality and delivery

Trelleborg Industrial Products India Pvt Ltd

(Deputy Manager – Supply Chain)Equipments from M/s Ceramed Engineers are standard in quality with good performance

Usha International Ltd

(Senior General Manager – R&D)Satisfied with the products supplied by Ceramed

Mr. Santanu Basu

(Senior General Manager – R&D - Usha International Ltd)1. Ceramed always supplies the best quality & productivity equipment. 2. Continuous availability of machine parts and spare parts. 3. Good service back-up.

Mr. Navin Khatri

(Senior Manager –Materials - Jindal Stainless (Hisar) Limited)Equipments from M/s Ceramed Engineers are standard in quality with good performance

Mr. Dimpath Monnappa p

(Minda Auto Components LTD.)Ceramed is committed to the work and has been providing us timely service as well as good customer support

D. Jawahar

Deputy Manager- PED Chains - L. G. Balakrishnan & Bros LtdCEL - Most important supplier with consistent in quality and delivery

Mr. Praveen Rotti

Deputy Manager – Supply Chain - Trelleborg Industrial Products India Pvt LtdSatisfied with the products supplied by Ceramed

Mr. Dimpath Monnappa P

Minda Auto Components LTD.Ceramed is committed to the work and has been providing us timely service as well as good customer support