- Home |

- CN Spiral Series

CN Spiral Series

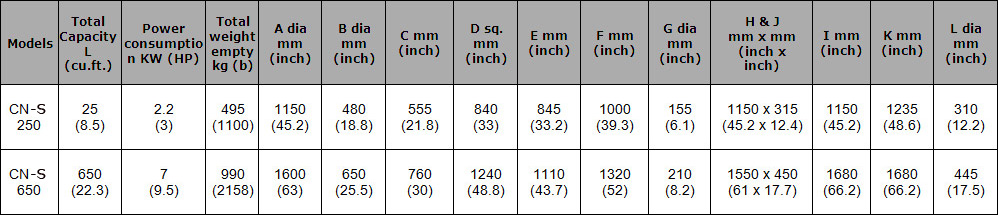

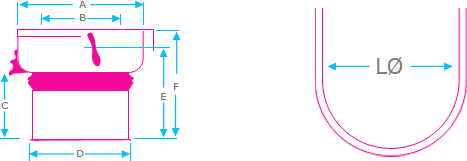

Description : CN-S Series – The automatic separation with a spiral type bowl design. (250 and 650 liter capacities only)

CN-S Series – The automatic separation with a spiral type bowl.

Vibratory machines use the principle of centrifugal force to cause vibrations to the work bowl thereby processing the components to the desired finish. The equipment comprises of a work bowl mounted on a rigid base frame.

Ceramed’sVibro finishing machine uses a powerful imported vibratory motor, made of special grade casting, and heavy duty spherical roller bearings. Springs are provided between the work bowl and base frame.

During operation, a mass of components along with a suitable ceramic media and chemical compound is introduced into the work bowl, the whole mixture rotates inside the bowl in a spiral and rotary motion causing the ceramic media to rub against the components continuously thus imparting the desired finish to the components.

Specification

Features

- Heavy duty flange type vibratory motor with adjustable amplitude for fast & effective process.

- Hot poured polyurethane lining with 12-16mm average thickness and the hardness approximately 75-80 shore A for long life.

- Raw materials and components used and quality standards employ for manufacture, ensure trouble free performance.

- The springs are specially designed to withstand heavy load and in the manner that they deliver spiral and rotary motion of the components and media in the bowl.

- Standard electrical switch gear items with safety features are provided along with the supply.

- The machine is mounted on anti-vibration pads.

- Only High tensile SS bolts are used.

Applications

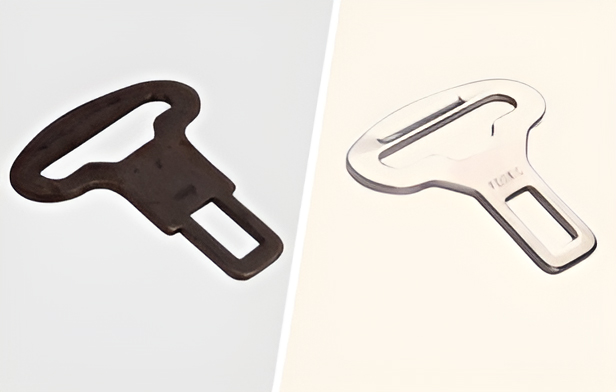

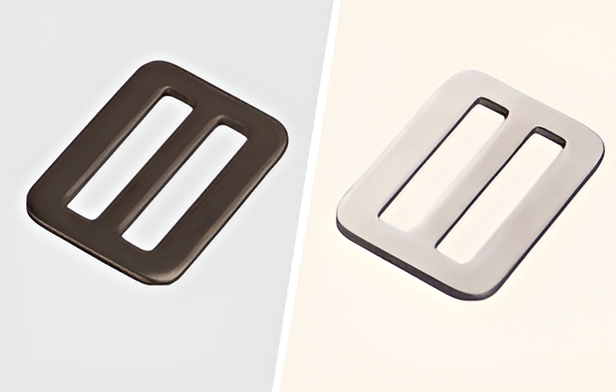

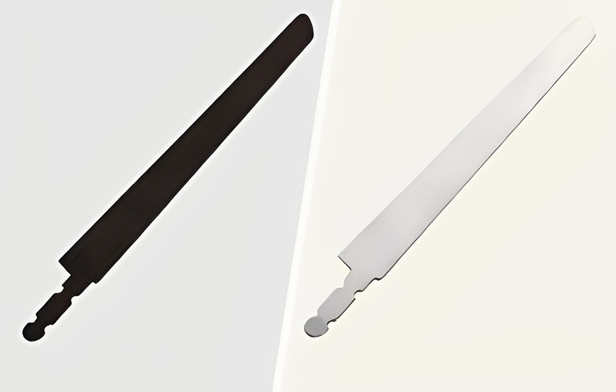

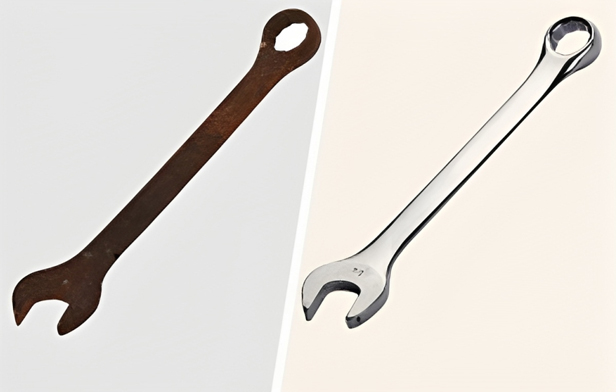

- Deburring

- Polishing

- Descaling

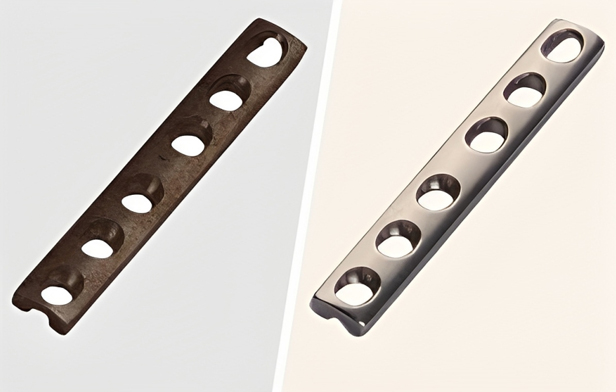

Before & After

Customer Experiences

Minda auto components ltd.

L. G. Balakrishnan & bros ltd (Deputy Manager- PED Chains)Ceramed is committed to the work and has been providing us timely service as well as good customer support

Jindal Stainless (Hisar) Limited

(Senior Manager –Materials)CEL - Most important supplier with consistent in quality and delivery

Trelleborg Industrial Products India Pvt Ltd

(Deputy Manager – Supply Chain)Equipments from M/s Ceramed Engineers are standard in quality with good performance

Usha International Ltd

(Senior General Manager – R&D)Satisfied with the products supplied by Ceramed

Mr. Santanu Basu

(Senior General Manager – R&D - Usha International Ltd)1. Ceramed always supplies the best quality & productivity equipment. 2. Continuous availability of machine parts and spare parts. 3. Good service back-up.

Mr. Navin Khatri

(Senior Manager –Materials - Jindal Stainless (Hisar) Limited)Equipments from M/s Ceramed Engineers are standard in quality with good performance

Mr. Dimpath Monnappa p

(Minda Auto Components LTD.)Ceramed is committed to the work and has been providing us timely service as well as good customer support

D. Jawahar

Deputy Manager- PED Chains - L. G. Balakrishnan & Bros LtdCEL - Most important supplier with consistent in quality and delivery

Mr. Praveen Rotti

Deputy Manager – Supply Chain - Trelleborg Industrial Products India Pvt LtdSatisfied with the products supplied by Ceramed

Mr. Dimpath Monnappa P

Minda Auto Components LTD.Ceramed is committed to the work and has been providing us timely service as well as good customer support